Bin Activator

Description

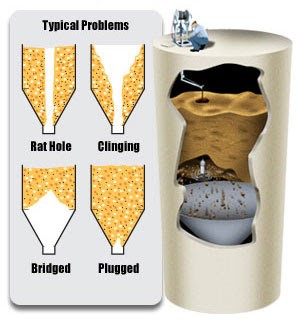

Placed under hopper. Facilitates discharge of powdery or granular materials from silo or hopper by vibration to eliminate outlet blocking and overcome formation of response angle.

Operation

- Composed of a steel or stainless steel cone, weld-free construction, integrated flange joint on top and bottom, silo connection brackets, and one or two electric vibrators. The unloading section must have a large diameter. A flange is welded to the silo cone. Special brackets and a technical polymer gasket form a flexible connection between the silo and the bin activator : one or two electric vibrators are mounted at the bottom on the side and vibrate the entire bottom, without vibrating the silo above it.

- During operation the bin activator describes a gyratory movement which is transmitted to the material inside the silo.

- The result is smooth material flow through the bin activator outlet into the connected feeder.

Benefit

- Ensure optimum feeding of the material according to a “mass flow” condition, thus avoiding bridging or rat holing phenomena

- Mechanical extraction without air or vibration and therefore without pollution or settling

- Fitting under the silo with a simple flange

- Works independent of load with full silo emptying

- Sealed, silent operation

- Easy to install: loose flange, adjustable length, flexible or rigid feeder