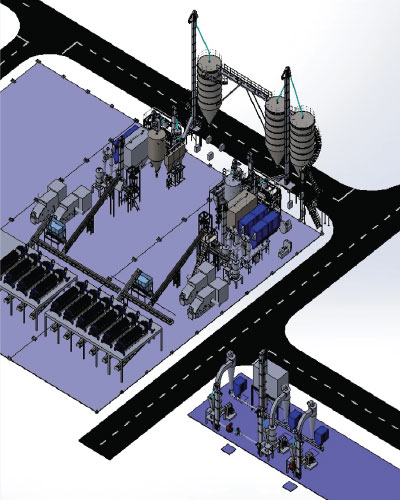

Bulk And Fluids Engineering (BAFE) have successfully delivered numerous significant plants integrated engineering projects as to various industrial and application.

- Turnkey Project for Plant Engineering, Automation & Integration

- Industry IoT, Smart SCADA & Instrumentation

- Bulk Material Handling & Fluids Process Engineering

- Mechanical & Pneumatic Conveying System

- Storage Silo Facilities, Bagging Lines & Palletizing System

- Computerized Weighing, Batching & Blending Plant

- Industrial equipment & machinery fabrication, assembly, installation & commissioning.

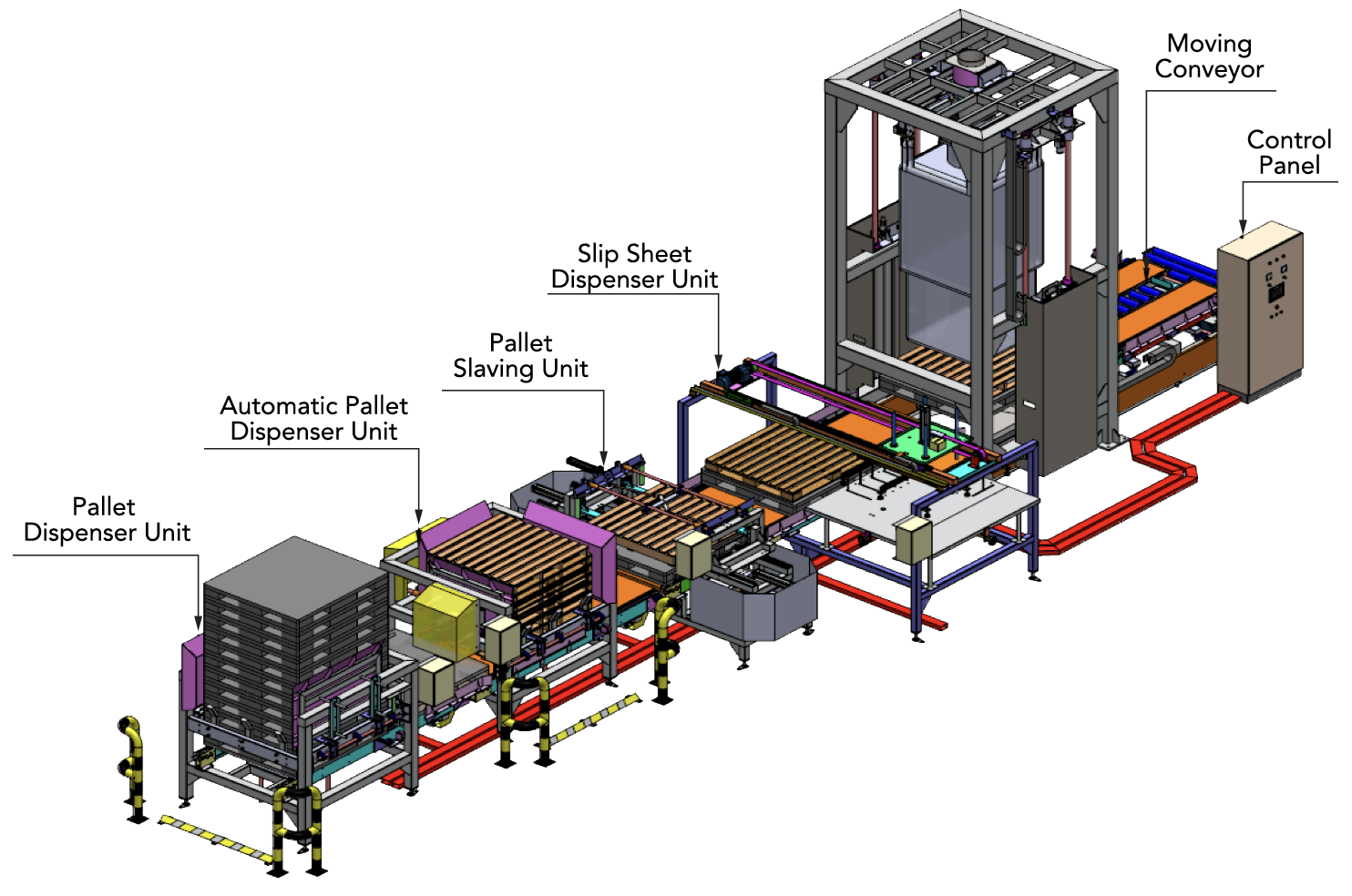

Automated FIBC Bagging System

What Are Automated FIBC Bagging Systems?

If you’re currently using FIBC in a production facility, then you know it’s quite a monumental task moving bags throughout your facility. Moving empty FIBC, filling them up with product, moving them across your facility to ship and/or discharge; it can be quite the manual process involving a lot of labor.

Automated FIBC Bagging System refer to the combination of multiple pieces of machinery that significantly reduce the amount of manual labor required to fill,

discharge, and transport bags throughout a facility Automated FIBC Bagging System can significantly reduce the amount of manual labor required to do all these tasks while simultaneously improving the overall safety of your facility.

FIBC Bagging System

automation between Packing Line and Warehouse operation

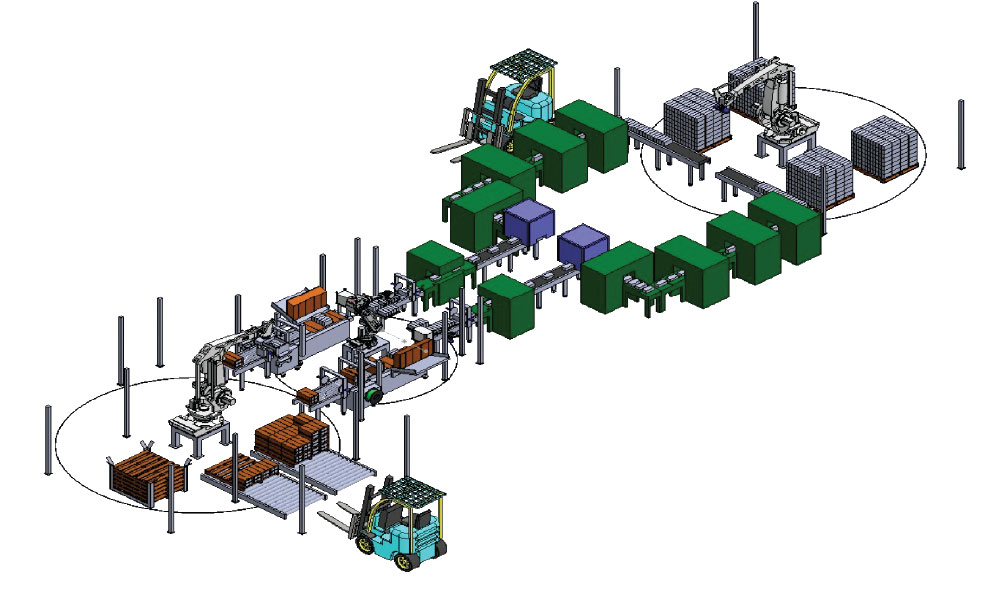

Robot Palletizing

Robotic Bricks Depalletizing, Handing, Packing

& Palletizing System

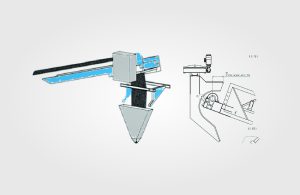

Batching & Blending

- We undertake complete Design, Engineering, Manufacture and Supply of Continuous Blending or Batch Mixing Plants on turnkey basis for various applications

- Whether your ingredients are free-flowing pellets, powders that pack, bridge or smear, products that fluidize, or blends prone to separation, our system can move them positively, weigh them accurately, and deliver them in prime condition.

We undertake complete Design, Engineering, Manufacture and Supply of Continuous Blending or Batch Mixing Plants on turnkey basis for various applications

Whether your ingredients are free-flowing pellets, powders that pack, bridge or smear, products that fluidize, or blends prone to separation, our system can move them positively, weigh them accurately, and deliver them in prime condition.

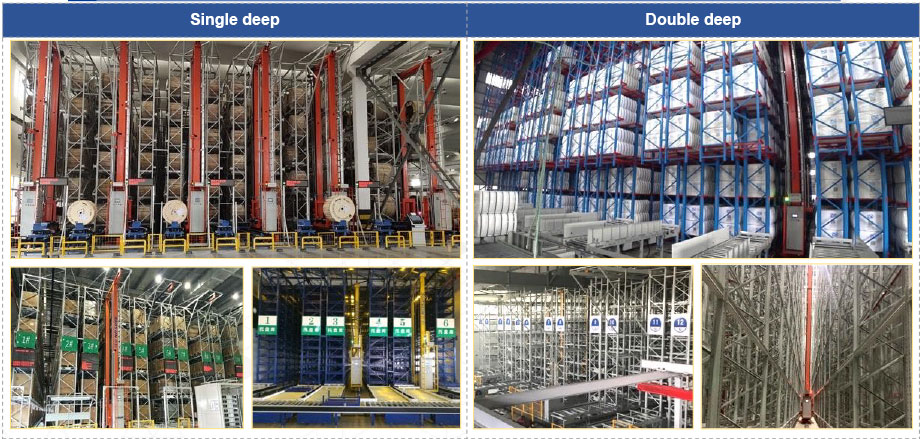

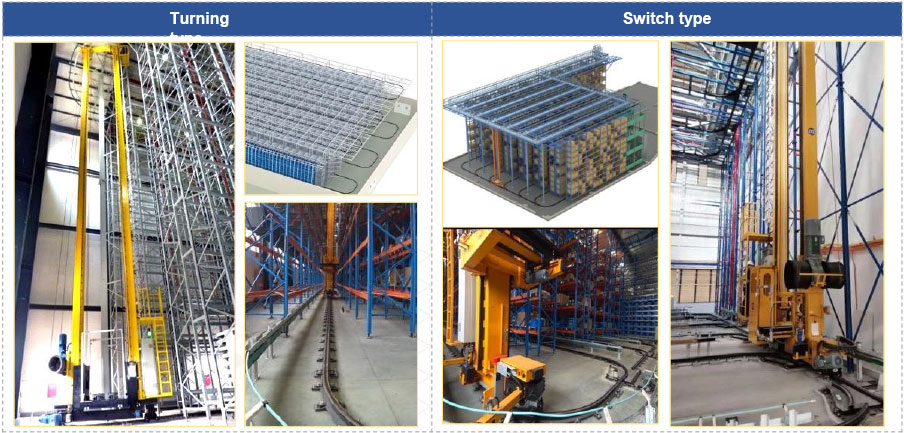

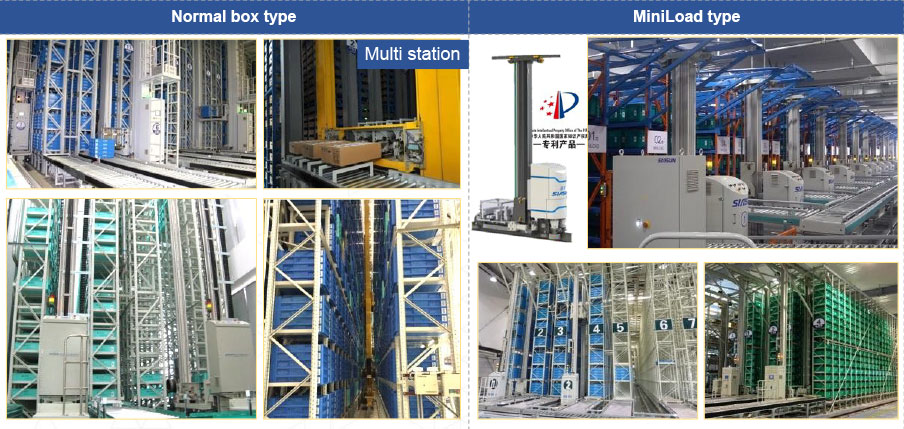

ASRS Warehouse

Moving pallets and packages around your warehouse is not always easy. We know that managing a warehouse has many challenges for distribution center managers like you. Some of these challenges include high labor costs, low productivity and efficiency, and high safety risks for employees. All these challenges can be overcome with automated storage and retrieval systems or ASRS!

ASRS system is programmed to operate according to the load dimensions and speed of delivery for a particular load type. ASRS sends information related to the load movement to the Warehouse Management Systems which processes the data and guide automated warehouse control systems (WCS) that maneuver other warehouse equipment in tandem.

How to Know That You

Need ASRS?

Every warehouse is different, so you will discover various things that may or may not reflect the situation in other warehouses. Yet, there are specific challenges that only ASRS can help you overcome and future-proof your operation:

- High upkeep costs (labor costs make 65% of the expenses of running a warehouse)

- Consistent errors in product or parts storage and retrieval operations

- Frequent employee injuries

- Low productivity and efficiency

- Too hot or cold work conditions

- Minimal use of vertical storage space

- Losing track of items in a warehouse

Metal Detector & Checkweigher

GLOBAL PARTNERS