What is IoT & IR4.0?

Industrial Internet of Things and Industry 4.0 – the names may change, but it is always about the seamless connection between the digital and real world. Using digital processes in industry allows manufacturing products in a more flexible, energy-efficient, resource-saving, individualized and inexpensive manner. BAFE is significantly driving this transformation towards connected and intelligent production.

How does Industrial

IoT & IR4.0 work?

Industrial IoT is a network of intelligent devices connected to form systems that monitor, collect, exchange and analyze data. Each industrial IoT ecosystem consists of:

- Connected devices that can sense, communicate and store information about themselves;

- Public and/or private data communications infrastructure;

- Analytics and applications that generate

- Business information from raw data;

- Storage for the data that is generated by the Industrial IoT devices;

- People

BENEFITS OF IIoT- INDUSTRIAL INTERNET OF THINGS

SOURCES: MORGAN STANLEY AUTOMATION WORLD INDUSTRIAL AUTOMATION SURVER, ALPHAWISE

0%

IMPROVING OPERATIONAL EFFICIENCY

0%

IMPROVING PRODUCTIVITY

0%

CREATING NEW BUSINESS OPPORTUNITIES

0%

REDUCING DOWNTIME

0%

MAXIMIZING ASSET UTILIZATION

0%

SELL PRODUCTS AS A SERVICE

0%

REDUCING ASSET LIFE CYCLE COSTS

0%

ENABLING WORKER SAFETY

0%

ENHANCING PRODUCT INNOVATION PROCESS

0%

BETTER UNDERSTANDING OF CUSTOMER BRAND

Industrial Applications

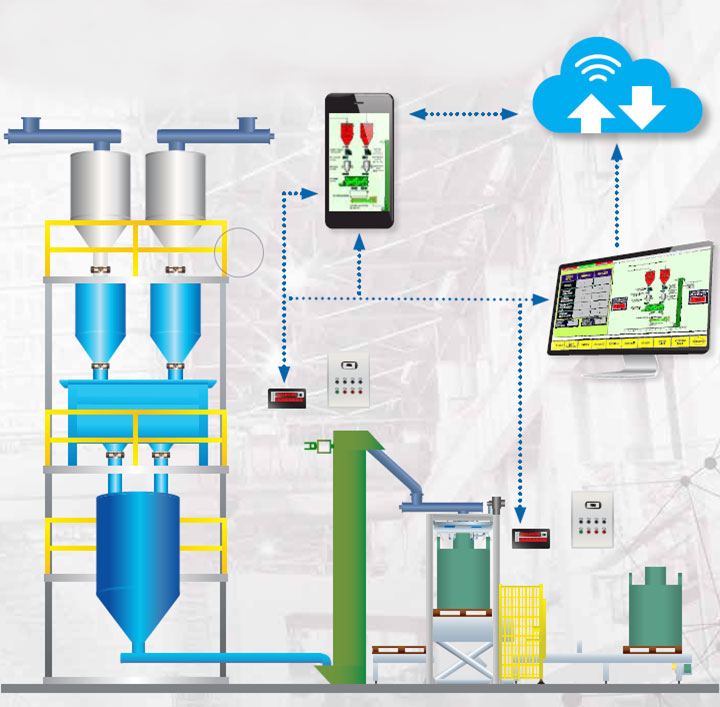

Batching & Blending System for FIBC

Packaging Line and Conveying System

- Real-time monitoring and controlling system for any batching and blending plant, on products transferring, feeding, weighing, blending, storage and extend to bagging and palletizing system.

- Capable to detect the plants machinery operation mode, running status, efficiency range, downtime as well as the selection of batching recipe, weighing accuracy and production throughput.

- The real-time monitored data and information can be captured and transmit via internal networking or external cloud system.

- All captured and stored data are sent to a network and plot into the client’s ERP system for production planning, preventive maintenance, inventory & delivery management, and good customer communication.

-

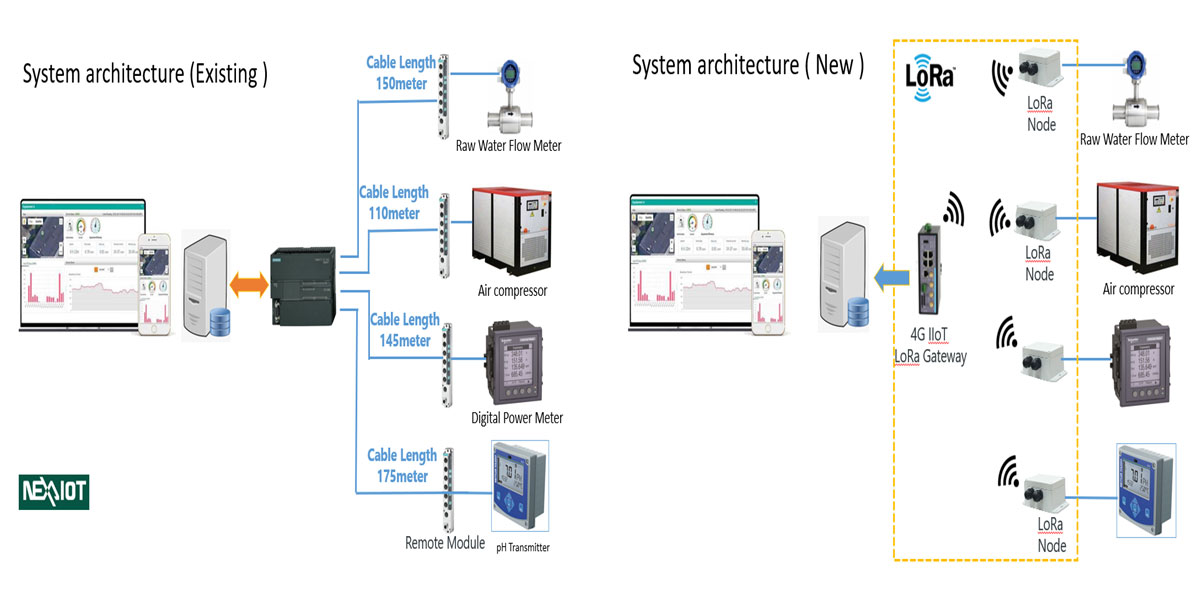

Wireless Process Monitoring – LoRA

Wireless Process Monitoring – LoRA

-

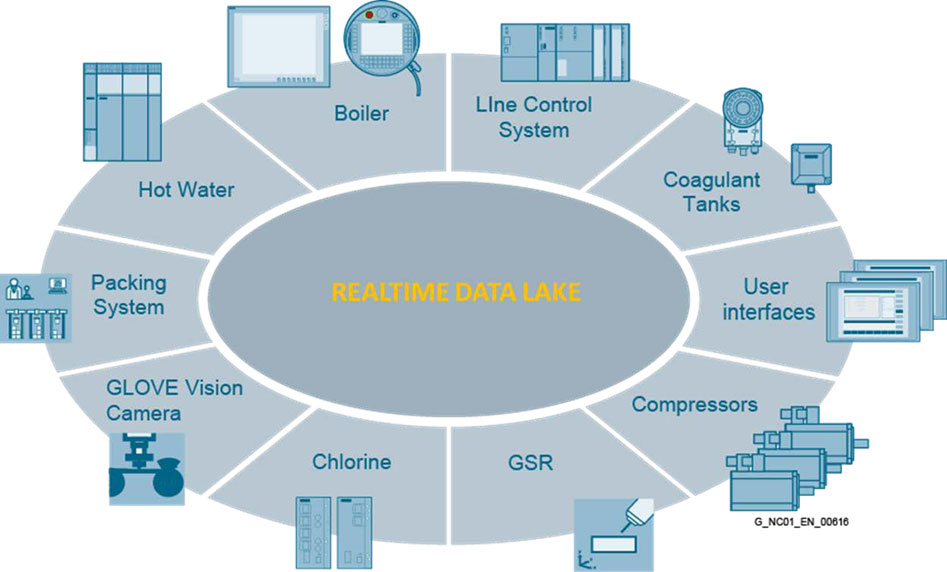

Glove Packaging – Traceability System

Glove Packaging – Traceability System

-

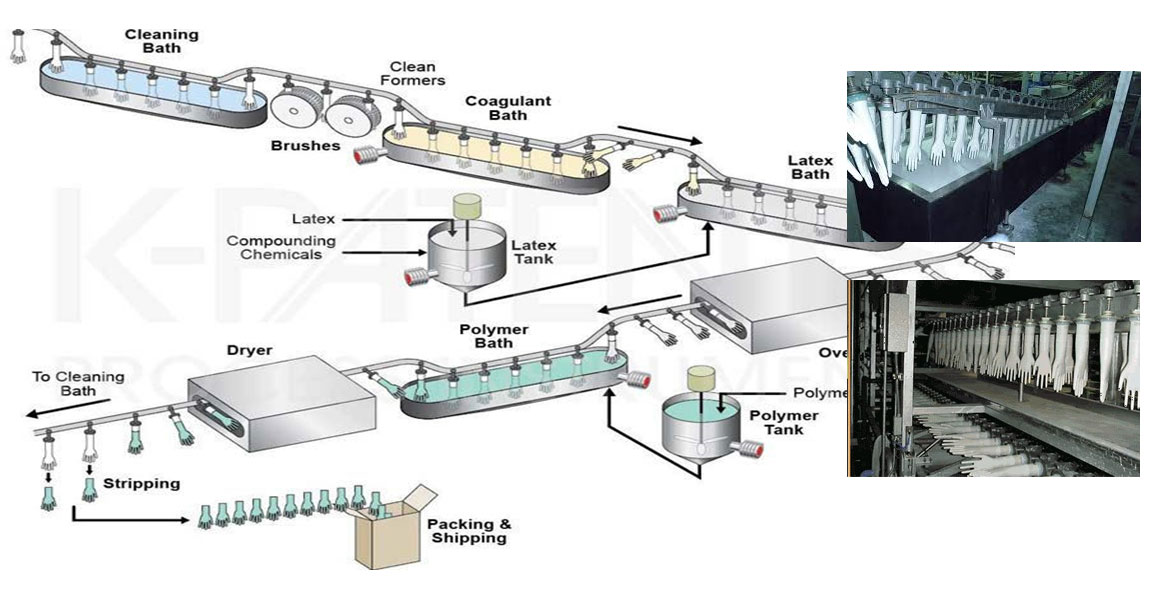

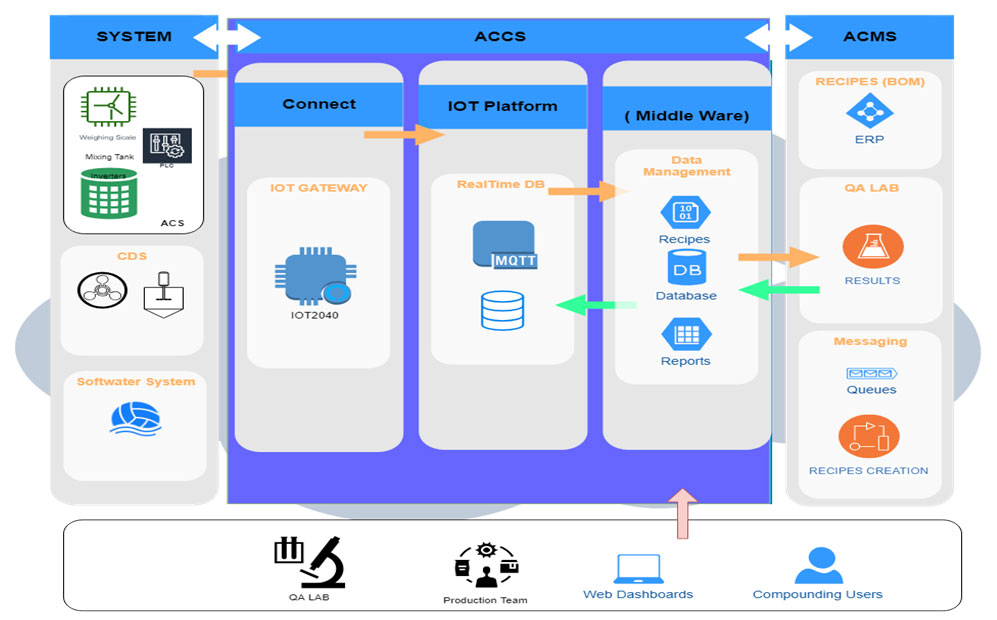

Auto Compounding Rubber Glove

Auto Compounding Rubber Glove

-

Connectivity Sub-System

Connectivity Sub-System

-

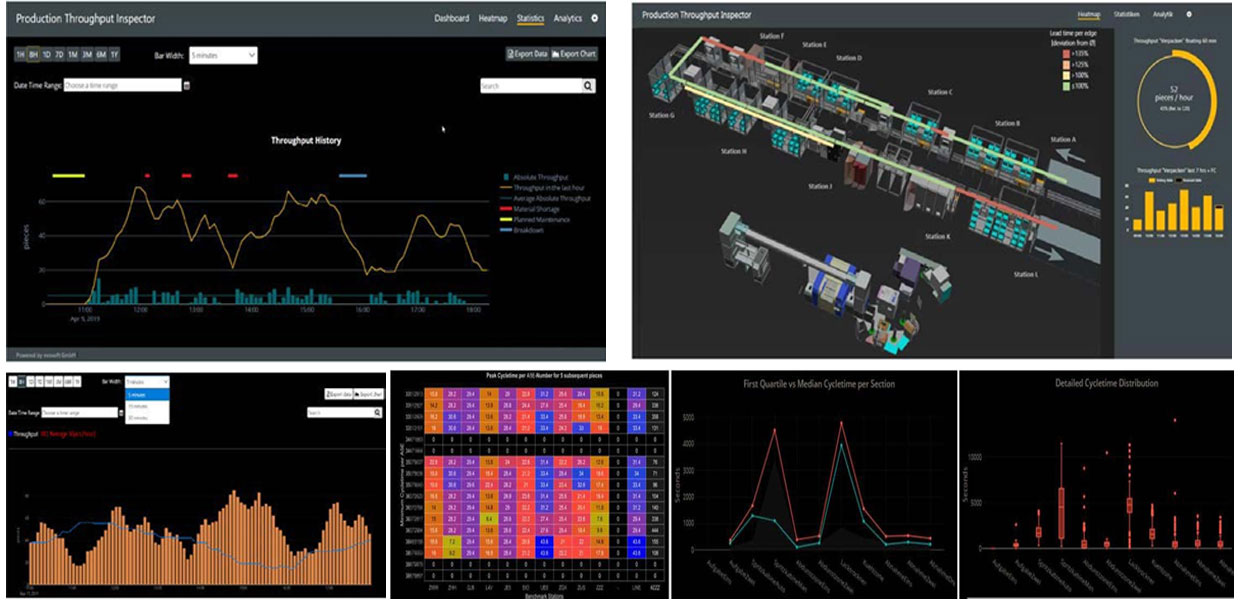

Dashboard

Dashboard

-

Auto Compounding Management System

Auto Compounding Management System

-

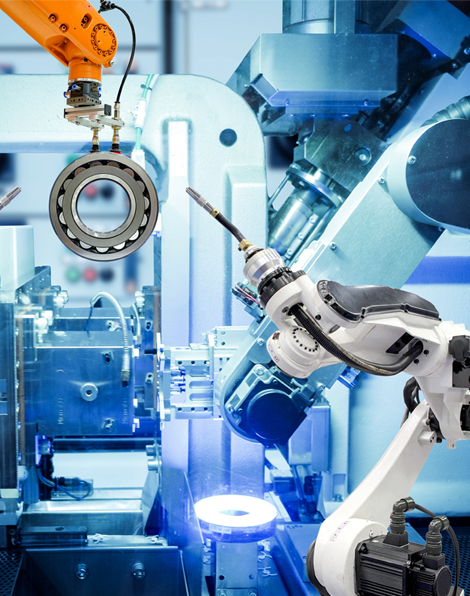

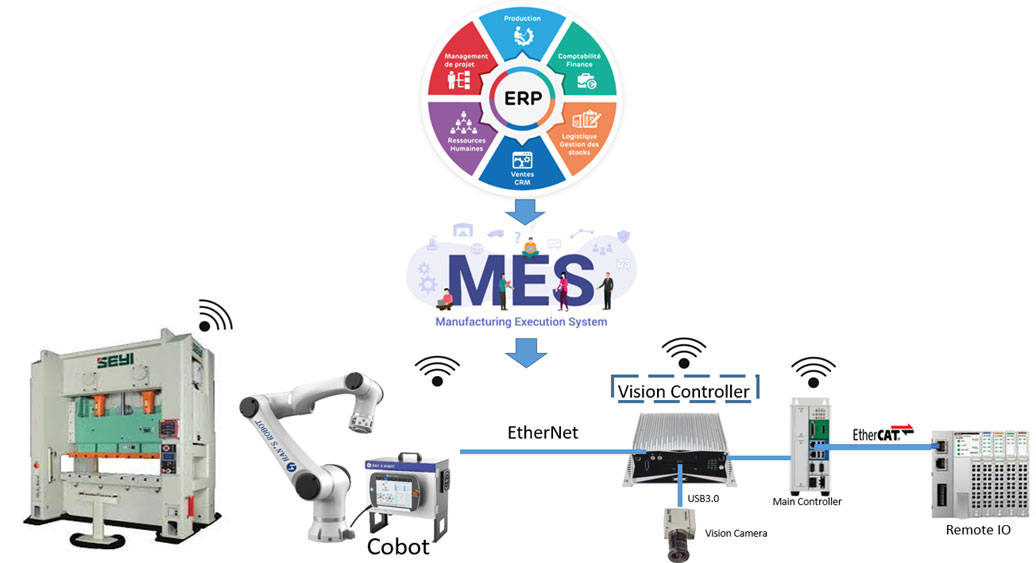

Intelligent Robotic Process Automation (RPA)

Intelligent Robotic Process Automation (RPA)

GLOBAL PARTNERS

Bulk and Fluids Engineering Sdn. Bhd. also known as BAFE, have been serving the market for nearly 20 years